Department of Mechanical Engineering Laboratories

CAD Lab

Computer Systems:

1) Lenovo Desktop (H50-50) MTM No.90B7007lin Sr.No.R301E2YZ/2X5, MTM NO.90B8002HIN Intel dual core 3.2GHz, 4GB Ram,500 GB HDD/,DvdrwDSDO5X KEY BOARD and Mouse wired with TFT

2)Lenovo Tft 18.5LED, MTM NO. 18201337 , SR NO.8ML1253F32N3021, MTM NO. 18201337 4ML1641F5201550/2402381/5201324/602840/201533201539

3) Think pad TFT 18.5″, MTM NO.60BDAAR6NP, SR NO. V901E94V

3-D PRINTER:

• Maximum Printable Area :200mm * 250mm * 200mm • Filament Diameter: 1.75mm • Extruder Diameter :0.4mm • Extruder Temperature :upto 270° C • Number Of Extruders: 2 • Model Of Extruders:Direct drive all metal dual Extruders • Recommended Materials:PLA, ABS, HIPS, PET-G, CARBON FIBRE, Flexible Filaments, Woodfill, Metafill, Polycarbonate etc. • Print Accuracy:80 – 150 microns • Maximum Print Speed:200mm/sec • Maximum Travel Speed:300mm/sec • Print Time:3 mins For 1 cubic cm part with 50% infill. • Layer Precision:0.1-0.30 mm • Heated Bed:Yes • Bed Temperature:90° C max • LCD Support:Yes • Connectivity:USB, SD card, wifi • Print Monitoring System:In build camera with Wifi connectivity

Scanner:

scanner Canon s.n. KKGE27044

Fluid Power Lab

Machines and Experimental setups : 20

1. Bernoulli’s Theorm Verification 2. Venturimeter Test Rig 3. Impact of Jet Apparatus 4. Flow through pipe in series and Parallel 5. Pelton turbine test Rig 6. Centrifugal Pump test Rig 7. Reciprocating Pump Test Rig 8. Impulse Turbine Model 9. Governing of reaction Turbine

Heat Transfer Lab

Experimental setups: 20

1. Determination of Thermal Conductivity of metal bar (Apparatus) 2. Thermal Conductivity of Insulating power (Apparatus) 3. Heat Transfer Through Composite wall Apparatus 4. Fin efficiency determination Apparatus 5. Stefan Boltzmann law Verification Apparatus 6. Forced convection (Determination of heat transfer coefficient)Apparatus 7. Natural convection (determination heat transfer coefficient)Apparatus 8. Pool & nucleate boiling (vertical heat transfer)Apparatus 9. Efficiency of cross flow heat exchanger Apparatus

Mechanics Of Material Lab

Machines: 20

1. Universal Testing Machine(Analog) 2. Conversion of Universal Testing Machine to Computer 3. Attachment with Universal Testing machine (Compression Test) 4. Impact Testing Machine 5. Torsion Testing Machine 6. Spring Testing Machine

Theory Of Machines Lab

Experiments setups : 20

1. Static and Dynamic Balancing of Machine 2. Gyroscopic Couple 3. Whirling Speed of shaft 4. Free and Damped Vibration of System with One DOF

Engineering Metallurgy Lab

Experiments setups : 20

1. Double disc Polishing Machine 2. Specimen belt Grinder 3. Jominy End Quench Test Apparatus 4. Binocular Metallurgical Microscope (Inclined) 5. Muffle Furnace 6. Metallurgical specimen box (set of 24) 7. Inverted trinocular Microscope (metzer) 8. USB CCD Camera for Microscopy 9. Microcam software for study ( Single licensed copy)

Manufacturing Process Lab

Machines: 20

1. Milling machine 2. Lathe Machines 3. Spot welding Machine 4. Gas welding. 5. MIG welding Machine

Production Technology Lab

Machines and Experimental Setups: 15

1. Optical profile projector ALMICRO make M.N. KW-800 2. Vernier bevel protector L.C. 5 Sec. 3. Slip gauge set metric 112 pieces W/g grade with T.C. 4. Dial Indicator 0.001mm

Energy Conversion Lab

Models

1. Babcock & Wilcox boiler model 2. Locomotive boiler 3. Benson Boiler 4. Green Economizer model

RAC Lab (Refrigeration and Air Conditioner lab)

1) VCR Test Rig

2) Domestic Refrigerator Cut Section Model

3) Room Air Conditioner

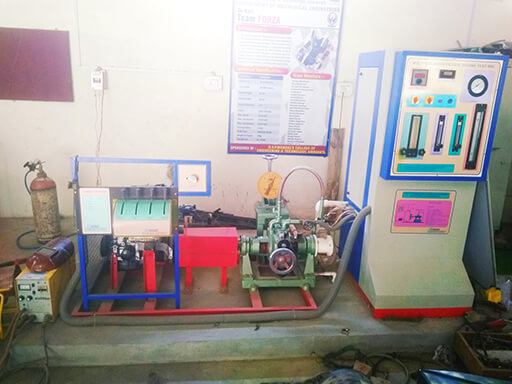

IC Engine Lab:

1) Morse Test Engine

2) Petrol Engine

3) Diesel Engine

4) Gas Analyzer

5) Cut Section Model of SI Engine

6) Cut Section Model of CI Engine

7) Cut Section Model of Carborator